Professional Fixed Belt Conveyor for Conveying Bukl Material Handling

- Model

- DTⅡ

Item specifics

- color

- customized

Review

Description

Professional Fixed Belt Conveyor for Conveying Bukl Material Handling

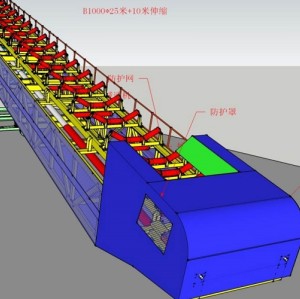

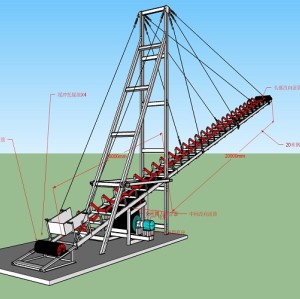

The belt conveyor is a kind of friction driven equipment which transports materials in a continuous way. It is mainly composed of frame, conveyor belt, idler, pulley, tensioning device, transmission device, etc. It can form a material conveying process from the initial feeding point to the final unloading point on a certain conveying line. It can not only transport the bulk materials, but also the finished products.

Fixed belt conveyors used in stone crushing or mineral processing plant. The conveyor belt moves according to the friction transmission principle. It is suitable for conveying powder, granular and small pieces of low abrasive materials and bagged materials, such as coal, gravel, sand, cement, fertilizer, grain, etc. The belt conveyor can be used in the range of - 20 ℃ to + 40 ℃ ambient temperature, and the temperature of the delivered material is less than 60 ℃. The captain and assembly form can be determined according to the user's requirements. The drive can be either electric roller or drive device with drive frame.

Features

- Strong power, cost saving, noise reduction, environmental protection, safety and reliability;

- Reducing resistance, improving accuracy, extending life, safety and reliability;

- Professional design Real material and compact structure Excellent performance;

- Modular design; This management concept creatively achieves the ultimate goal of cheap and fast delivery of the SKE series fixed belt conveyor

Model | Belt Width (mm) | Inclined Angle (°) | Recommended angle (°) | Belt Speed (m/s) | Recommended belt speed (m/s) | Capacity (tph) |

SKE500 | 500 | 0.8/1.0/1.25/1.6 | 160 | |||

SKE650 | 650 | 0.8/1.0/1.25/ 1.6/2.0 | 290 | |||

SKE800 | 800 | 1.6/2.0/3.15 | 450 | |||

SKE1000 | 1000 | 700 | ||||

SKE1200 | 1200 | 1000 | ||||

SKE1400 | 1400 | 1500 |

The conveying capacity is calculated according to the material bulk density of 1.6t / m3, the operation stacking angle of 20 °, the idler groove angle of 35 °, and the belt speed of 1.6m / s.

Max conveying capacity | |||||||||

Belt Width (mm) | Inclined coefficient | Bulk density (t/m³) | Conveying capacity based on different belt speed (tph) | ||||||

0.8 | 1.0 | 1.25 | 1.6 | 2.0 | 2.5 | 3.15 | |||

500 | 80 | 100 | 125 | 160 | 200 | 250 | -- | ||

650 | 140 | 180 | 230 | 290 | 360 | 450 | 570 | ||

800 | 230 | 280 | 360 | 450 | 560 | 700 | 900 | ||

1000 | 370 | 460 | 580 | 700 | 900 | 1100 | 1400 | ||

1200 | 550 | 650 | 850 | 1000 | 1300 | 1600 | 2000 | ||

1400 | 700 | 900 | 1100 | 1500 | 1900 | 2300 | 2900 | ||

Remark:

The different inclined angle and inclined coefficient match relations:

0~2°,1;3~4°,0.99;5~6°,0.98;7~8°,0.97;9~10°,0.95;11~12°,0.93;13~14°,0.91;15~16°,0.89;17~18°,0.85