DX series fixed Belt Conveyor used in metallurgy, mines, coal, power station, building materials

- Model

- B800/B1000/B1200/B1400/B1600/B1800/B2000

Item specifics

- Color

- Customized

- Application

- aggregate/ mix batch plant/ grain/coal etc

Review

Description

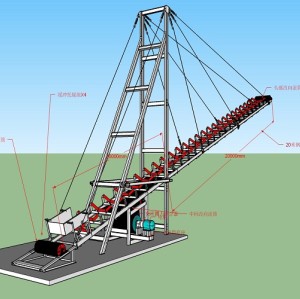

Product Description

Description

DX series fixed Belt Conveyor used in metallurgy, mines, coal, power station, building materials:The universal series design - DX steel cord belt conveyor is a high-strength conveyor, which is suitable for large-volume and long-distance transportation of bulk materials. It can transport materials with a bulk density of 0.8~2.5t/m3. The working environment temperature is generally -20~40 °C. In cold regions, the driving part should have heating conditions. The conveying distance reach several kilometers; The conveying capacity is large, and the conveying capacity is 400~9600m3/h. The elongation of the conveyor belt is small, about 1/5 of the ordinary belt. The service life is 2~3 times longer than the ordinary belt.

It can be used in out-door, better to be configured with corridors or protective covers whenever possible. According to the customer's conveying process requirements, our company can design, calculate and combine the whole and the entire conveyor line according to different terrains and working conditions.

Application:

Widely used in continuous conveying systems such as metallurgy, coal, transportation, electric power plant, mining, chemical ;

Features:

1. Wide range of conveying materials, large conveying capacity, wide range of conveying lines,

2. Simple structure, reliable, strong in safety, low in noise and low in pollution.

3. High efficiency, low energy consumption, low operating costs, and capital investment

Technical Specification

Width | Conveyor Belt Strength GX (N/mm) | Speed (m/s) |

||||||||||||||

650 | 800 | 1000 | 1250 | 1600 | 2000 | 2500 | 3000 | 3500 | 4000 | |||||||

Max Tension Allowed (KN) | 2.0 | 2.5 | 3.15 | 4.0 | 5.0 | |||||||||||

800 | DX3 | 52 | 64 | 80 | 100 | 128 | 160 | 200 | 240 | 280 | 320 | √ | √ | √ | -- | -- |

1000 | DX4 | -- | 80 | 100 | 125 | 160 | 200 | 250 | 300 | 350 | 400 | √ | √ | √ | -- | -- |

1200 | DX5 | -- | -- | 120 | 150 | 192 | 240 | 300 | 360 | 420 | 480 | √ | √ | √ | √ | -- |

1400 | DX6 | -- | -- | -- | 175 | 224 | 280 | 350 | 420 | 490 | 560 | √ |

√

|

√

|

√

|

√

|

1600 | DX7 | -- | -- | -- | -- | 256 | 320 | 400 | 480 | 560 | 640 | √ | √ | √ | √ | √ |

1800 | DX8 | -- | -- | -- | -- | 288 | 360 | 450 | 540 | 630 | 720 | √ | √ | √ | √ | √ |

2000 | DX9 | -- | -- | -- | -- | -- | 400 | 500 | 600 | 700 | 800 | √ |

√

|

√

|

√

|

√

|

Remark:

1. It can be designed to 51 different model conveyors based on different conveyor belt wideth and strenght.

2. The max tension is calculated by n=10.

Conveying Capacity

Speed (m/s) | ||||||

2.0 | 2.5 | 3.15 | 4.0 | 5.0 | ||

Capacity (t/h) | ||||||

|

DX3

|

800 | 388-550 | 485-688 |

612-865

|

--

|

--

|

DX4 | 1000 | 632-888 | 790-1110 | 1000-1400 | -- | -- |

DX5 | 1200 | 926-1300 | 1158-1625 | 1460-2050 | 1852-2600 | -- |

DX6 | 1400 | 1276-1800 | 1595-2250 | 2010-2830 | 2552-3600 | 3190-4500 |

|

DX7

|

1600 | 1700-3070 | 2125-2975 |

2680-3850

|

3400-4760

|

4250-5950

|

|

DX8

|

1800 | 2180-3070 | 2725-3838 |

3440-4840

|

4360-6140

|

5450-7675

|

|

DX9

|

2000 | 2740-3840 | 3425-4800 |

4230-6050

|

5480-7680

|

6850-9600

|

Remarks:

1.The data is calculated based on the groove angle=30°.

2.The capacity range will be different due to the material’s bulk density.

Product Display