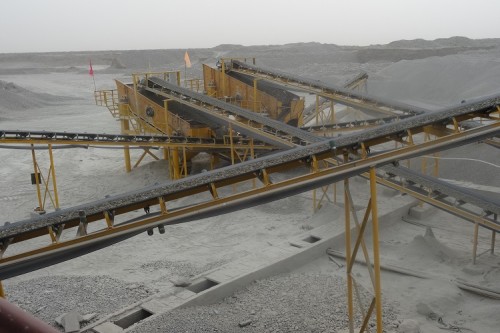

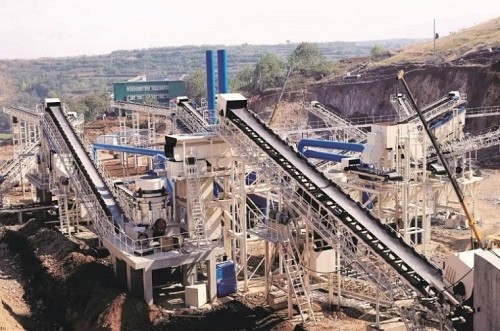

Fixed belt conveyors used in stone crushing or mineral processing plant

- Model

- /B500B650/B800/B1000/B1200/B1400

Item specifics

- Color

- Customized

- Application

- aggregate/ mix batch plant/ grain/coal etc

Review

Description

Description

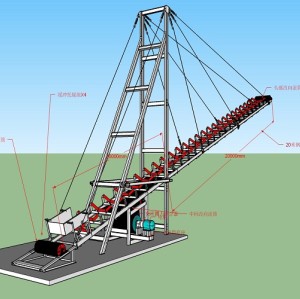

The belt conveyor is a kind of friction driven equipment which transports materials in a continuous way. It is mainly composed of frame, conveyor belt, idler, pulley, tensioning device, transmission device, etc. It can form a material conveying process from the initial feeding point to the final unloading point on a certain conveying line. It can not only transport the bulk materials, but also the finished products.

Fixed belt conveyors used in stone crushing or mineral processing plant. The conveyor belt moves according to the friction transmission principle. It is suitable for conveying powder, granular and small pieces of low abrasive materials and bagged materials, such as coal, gravel, sand, cement, fertilizer, grain, etc. The belt conveyor can be used in the range of - 20 ℃ to + 40 ℃ ambient temperature, and the temperature of the delivered material is less than 60 ℃. The captain and assembly form can be determined according to the user's requirements. The drive can be either electric roller or drive device with drive frame.

Applications

Belt conveyors are widely used in crushing plants, mineral ore processing plant , cement plant etc

Specifications

Belt Width (mm) |

Belt Length(m)/Power(kw) |

Speed (m/s) |

Capacity (tph) |

||

400 | =<12/1.5 | 12-20/2.2-4 | 20-25/4-7.5 | 40-60 | |

500 | =<12/3 | 12-20/4-5.5 | 20-30/5.5-7.5 | 50-80 | |

650 | =<12/4 | 12-20/5.5 | 20-30/7.5-11 | 130-230 | |

800 | =<6/4 | 6-15/5.5 | 15-30/7.5-15 | 280-320 | |

1000 | =<10/5.5 | 10-20/7.5-11 | 20-40/11-22 | 430-850 | |

1200 |

=<10/7.5 | 10-20/11 | 20-40/15-30 |

650-1280 |

|

1400 |

=<10/3-11 | 10-20/5.5-22 | 20-40/22-55 |

700-1430 |

|

1600 |

=<10/3-15 | 10-20/11-30 | 20-40/30-75 |

750-1850 |

|