China brand Corrugated conveyor belt sidewall used for concrete mixed plant

- Model

- B400/B500/B650/B800/B1000/B1200/B1400

Item specifics

- color

- Black

- belt width

- 500-1400mm

- Material with core:

- CC-56, NN100, NN150, NN200, NN300, NN400

Review

Description

Description

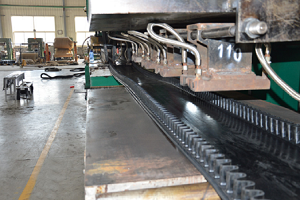

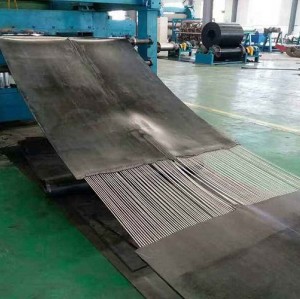

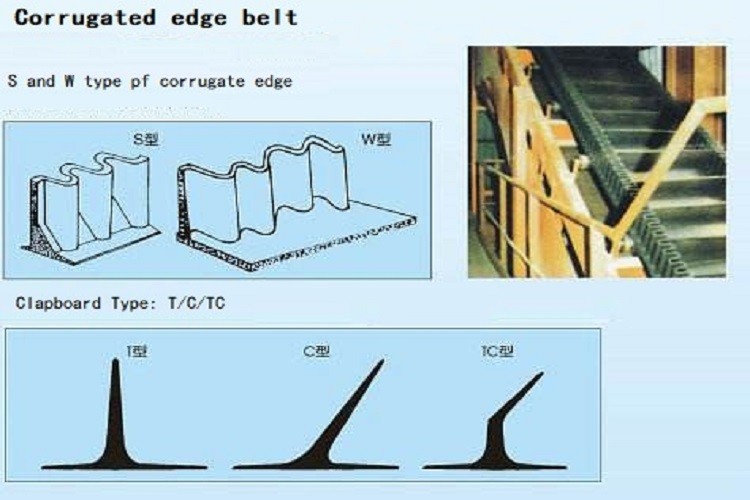

China brand Corrugated conveyor belt sidewall used for concrete mixed plant : The high-inclined corrugated-shaped Belt is composed of base belt, rib and transverse partition. The ribs prevent the material from slipping and falling. In order to easily bypass the drum, the ribs are designed in a corrugated shape; The role of the transverse partition is to support the material. In order to achieve a large inclination, the T-type TC types are widely used. The ribs and the transverse partition are connected to the base belt by a secondary vulcanization method, which has high connection strength;

Type of corrugated conveyor belt (ordinary large-inclined corrugated conveyor belt):

According to the performance of the covering rubber, it can be divided into ordinary type, heat-resistant type, flame-resistant type, cold-resistant type, acid-base type, oil-resistant type

Feature

The corrugated type conveyor belt can be used while conveyor inclined angle is generally ≥30°. It can also be used with general belt conveyors for horizontal and short-distance transportation (no partition is generally set).

The corrugated edge conveyor belt is made by vulcanizing the base belt with the groove degree not greater than 0.03, the side rib (Side wall), and the horizontal partition (optional for horizontal transportation) made by the double vulcanization process.

Compared with the similar products made by the gluing process, the corrugated edge conveyor belt made by the double vulcanization process has high bonding strength and good flexibility. Phenomenon, which can greatly extend the service life;

Specifications

Corrugated Flanged Conveyor Belt (Ordinary Large Inclined Corrugated Flanged Conveyor Belt) Specifications:

(1) Material with core: ;

(2) Belt width: 100mm-2400mm;

(3) Cord layer: 2-10 layers;

(4) Cover rubber:

Working rubber: 1.5-8mm;

Non-working rubber: 1mm-4.5mm

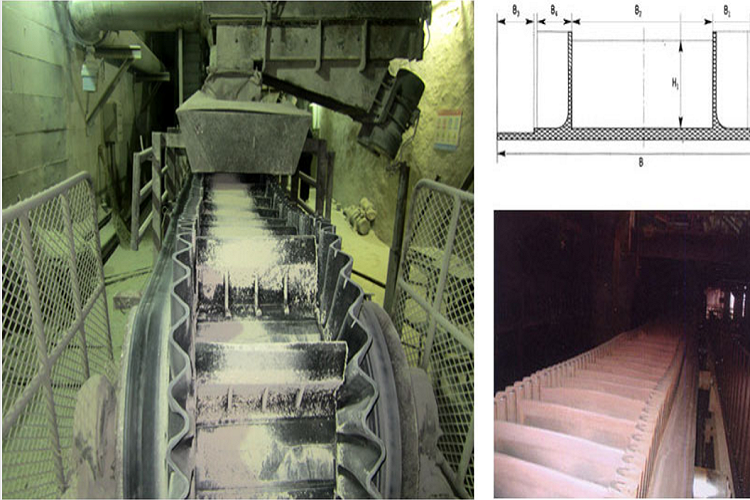

Simple Drawing

Basic Belt Width |

Rib height H |

Cross diaphragm height H1 |

Bottom width B1 |

Effective bandwidth B2 | Empty edge width B3 |

40 | 35 | 25 | 180 | 35 | |

60 | 55 | 50 | 120 | 40 | |

80 | 75 | ||||

60 | 55 | 50 | 180 | 60 | |

80 | 75 | ||||

100 | 90 | ||||

80 | 75 | 50 | 250 | 75 | |

100 | 90 | ||||

120 | 110 | ||||

100 |

90 |

50 |

350 | 100 | |

120 |

110 |

||||

160 |

140 |

75 |

300 | ||

1000 | 120 | 110 | 50 | 460 | 120 |

160 | 140 | 75 | 410 | ||

200 | 180 | ||||

1200 | 160 | 140 | 75 | 550 | 120 |

200 | 180 | ||||

240 | 220 | ||||

1400 | 160 | 140 | 75 | 690 | 180 |

200 | 180 | ||||

240 | 220 | ||||

300 | 260 | 100 | 640 | ||

1600 | 200 | 180 | 75 | 830 | 210 |