NN or EP core Conveyor Belt 3 plies, 4 plies with rubber cover

- Model

- B500/B650/B800/B1000/B1200/B1400

Item specifics

- color

- Black

- tickness

- 8-16mm

- cord material

- Nylon or EP

- Belt width

- 500-2000mm

Review

Description

Description

NN or EP core Conveyor Belt 3 plies, 4 plies with rubber cover: Conveyor belt, is a rubber and fiber, metal composite product, or a plastic and fabric composite product used in belt conveyors to carry and carry materials.

Conveyor belts are widely used in cement, coking, metallurgy, chemical, steel and other industries where the transportation distance is short and the transportation volume is small.

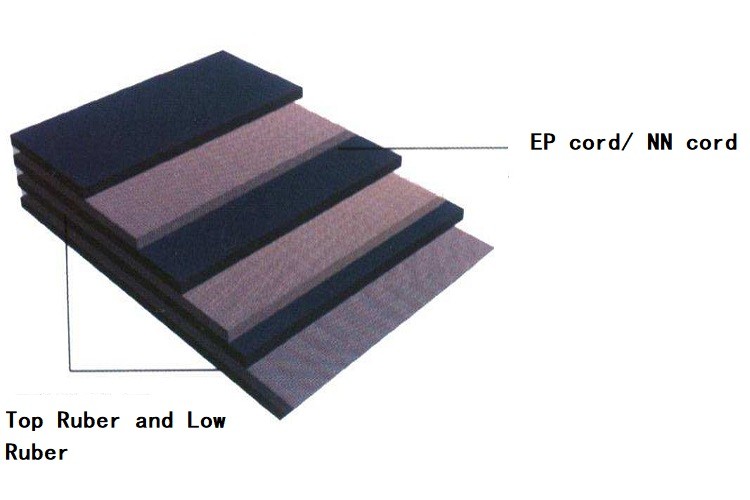

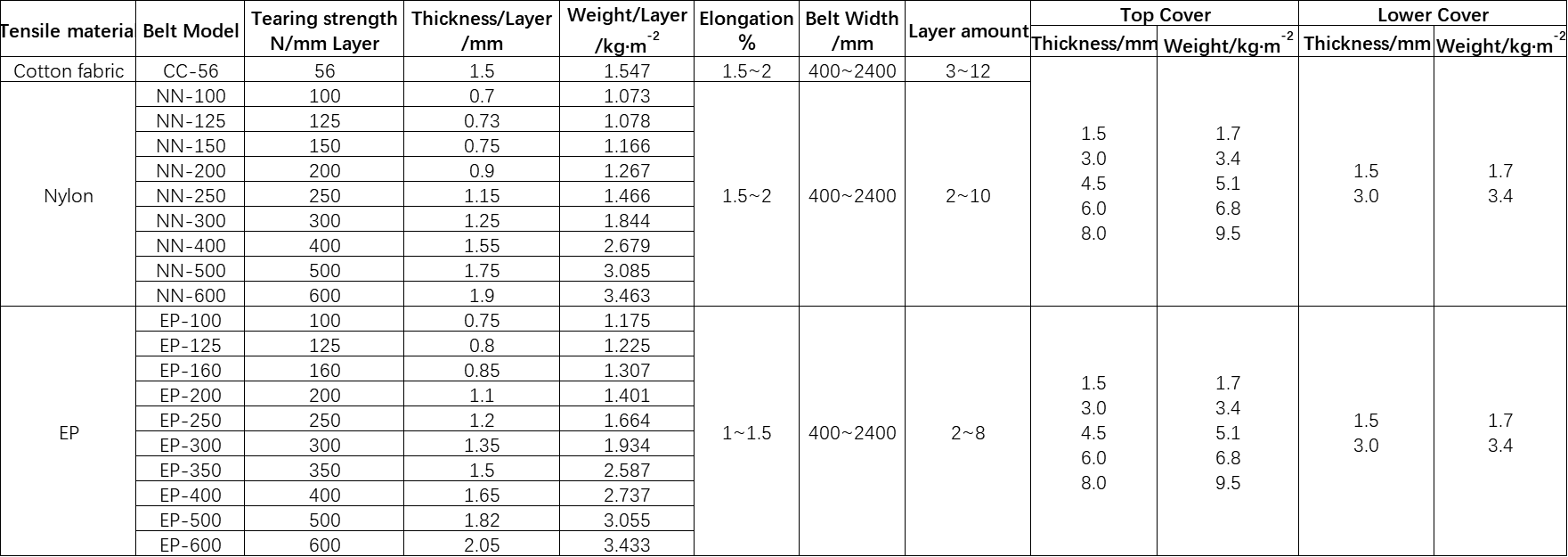

Core material: common cotton canvas (CC), nylon (NN), polyester (EP), etc.

The surface can be designed into various patterns according to the requirements of application;

According to their characteristics, conveyor belts can be divided as below:

1. Heat-resistant conveyor belt: it is made of multi-layer rubber cotton canvas (polyester cotton cloth) or polyester canvas covered with high-temperature or heat-resistant rubber, which is bonded together by high-temperature vulcanization. It is suitable for convey hot coke and cement below 175 °C. , Slag and hot castings;

2. The flame-retardant conveyor belt, also known as the whole core flame-retardant conveyor belt, is made of the entire belt core after being plasticized or vulcanized by impregnation with a polyvinyl chloride impregnating paste. At the same time, the product has good flame retardant, antistatic, impact resistance, wear resistance, corrosion resistance and other properties;

3, Cold resistant conveyor belt, choosed by cotton canvas, nylon canvas or polyester canvas as the core, cover rubber using natural rubber and butadiene rubber, a combination of high elasticity, impact resistance, cold resistance, etc. It is normally used in the environment.

4, Acid and alkali resistant conveyor belt, a kind of working environment suitable for bulk material with acid and alkali, such as phosphate fertilizer manufacturing, seawater sun salt, covering rubber using rubber and plastic blending and filled with inert materials excellent in acid and alkali resistance.

Simple Structure

Specification

Physical and mechanical properties of cover rubber

Performance level of cover layer |

Tensile strength ≥ |

Break elongation ≥ |

Abrasion amount ≤ |

MPa |

% |

mm3 |

|

H (Hard) | 24 | 450 | 120 |

D (Middle) |

18 |

400 |

100 |

L (Low) |

15 |

350 |

200 |

Full thickness tensile properties:

a, The longitudinal tensile strength of the belt is not lower than the following nominal values: 160, 200, 250, 315, 400, 500, 600, 630, 800 N / mm

b. The longitudinal break elongation of the full thickness of the belt shall not be less than 10%. The longitudinal reference force elongation of the full thickness of the belt shall not be greater than 4%.

c, Straightness: not more than 25mm

d. Adhesive strength between layers:

|

|

Adhesive strength between cords

|

Adhesive strength between cord and covers

|

|

|

Cover thickness ≤1.5mm

|

Cover thickness>1.5mm

|

||

|

Average of all samples

|

3.2N/mm

|

2.1N/mm

|

2.7N/mm

|