KS Large Inclined Corrugated Sidewall Belt Conveyor systems for Concrete Aggregate

- Model

- KS

Item specifics

- color

- customized

Review

Description

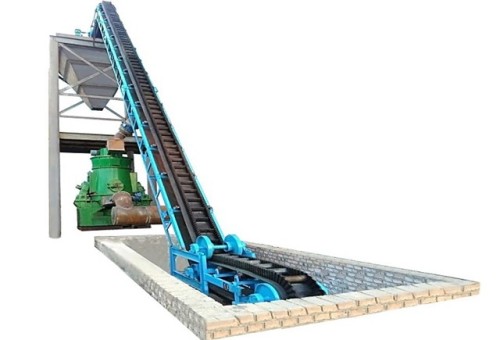

KS Large Inclined Corrugated Sidewall Belt Conveyor systems for Concrete Aggregate

SKE KS Corrugated Sidewall Belt Conveyor, which is also known as large inclination belt conveyor and high/steep angle belt conveyor. The biggest feature of the structure is to replace the ordinary belt with corrugated sidewall belt. Its structural composition and working principle are the same as the general belt conveyor.

Advantages

1.Conveying angles are able up to 90°

2.Simple structure, small footprint, low noise

3.As reliable as a universal belt conveyors

4.No internal friction energy loss and save power

5.Able to be linked with different flat belt conveyors

6.Large conveying capacity for bulk materials handling

Application

KS Corrugated Sidewall Belt Conveyor systems have the advantage of large conveying capacity, taking small footprint, few malfunction, low noises, low running costs, etc. Therefore, it is widely used in the location of port and mine, metallurgy, mining, coal, power stations, building materials(sand, aggregate, gravel, concrete, etc), chemicals, light industry, machinery, petroleum, grain and other industries.

Tech Datasheet

| Specifications of Corrugated Sidewall Belt Conveyor | |||||

|---|---|---|---|---|---|

| Belt width(mm) | Height of ribs (mm) | Belt speed(m/s) | Angles(β/(°)) | Conveying Capacity (m3/h) | Power(kW) |

| 300 | 40 | 0.8~2.0 | 30~90 | 18 | 1.5~18.5 |

| 60 | 24 | ||||

| 80 | 40 | ||||

| 400 | 60 | 0.8~2.0 | 34 | 1.5~18.5 | |

| 80 | 60 | ||||

| 10 | 80 | ||||

| 500 | 80 | 0.8~2.0 | 84 | 1.5~18.5 | |

| 100 | 112 | ||||

| 120 | 98 | ||||

| 650 | 100 | 0.8~2.0 | 156 | 1.5~2.2 | |

| 120 | 140 | ||||

| 160 | 186 | ||||

| 800 | 120 | 0.8~2.5 | 186 | 2.2~5.5 | |

| 160 | 318 | ||||

| 200 | 360 | ||||

| 1000 | 160 | 1.0~2.5 | 428 | 4.0~75 | |

| 200 | 483 | ||||

| 240 | 683 | ||||

| 1200 | 160 | 1.0~3.15 | 535 | 5.5~110 | |

| 200 | 765 | ||||

| 240 | 1077 | ||||

| 300 | 1358 | ||||

| 1400 | 200 | 1.0~3.15 | 920 | 5.5~160 | |

| 240 | 1298 | ||||

| 300 | 1657 | ||||

| 400 | 2381 | ||||

| 1600 | 200 | 1.25~3.15 | 1074 | 5.5~160 | |

| 240 | 1515 | ||||

| 300 | 1953 | ||||

| 400 | 2807 | ||||

| 1800 | 240 | 1.25~4.0 | 2200 | 7.5~185 | |

| 300 | 2724 | ||||

| 400 | 4106 | ||||

| 500 | 5036 | ||||

| 2000 | 240 | 1.25~4.0 | 2480 | 11~220 | |

| 300 | 3236 | ||||

| 400 | 4648 | ||||

| 500 | 5736 | ||||

| 2200 | 300 | 1.25~4.0 | 3612 | 11~220 | |

| 400 | 5192 | ||||

| 500 | 6432 | ||||

| 630 | 7820 | ||||

| 2400 | 300 | 1.25~4.0 | 3992 | 11~220 | |

| 400 | 5736 | ||||

| 500 | 7132 | ||||

| 630 | 8668 | ||||

| The conveying capacity in the table is calculated according to the inclination of 30 °, the maximum belt speed allowed by this specification, and the minimum distance between the diaphragms. | |||||