Loading and unloading belt conveyor system for railway station transportation

- Model

- KC1/KC2/KY1/KY2

Item specifics

- Color

- Customized

- Processing Capacity

- 200-2000 tph

- Pulley Lagging

- To be confirmed by Client

- Length

- 10- 300 mtrs

Review

Description

Train unloading / discharging Loading System

Description

SKE machinery is focusing on bulk material loading and unloading belt conveyor system design, which are widely used in many fields.

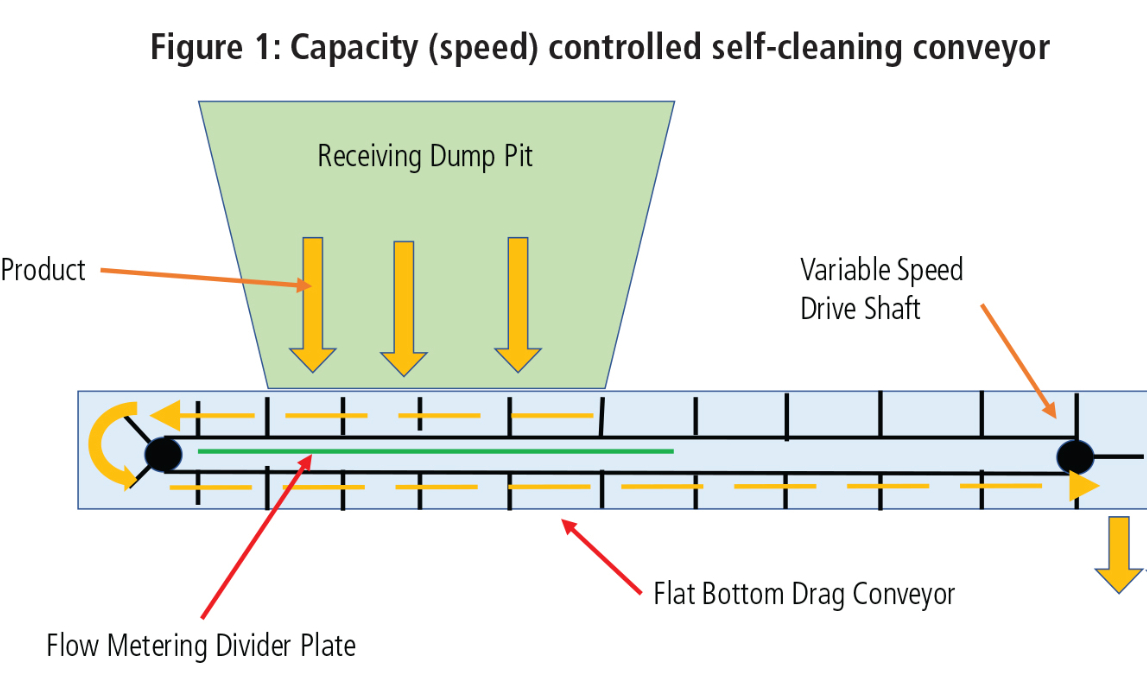

Train transportation (Railway) as the most economical solution for bulk material, such as coal, grain, aggregate, mineral ore etc. So a right and reasonable railway loading and unloading belt conveyor system is critical . The complete system can be composed by several conveyors or single conveyor; For unloading system, there will be a receiving belt conveyor under the receiving chute or hopper below the railway, and other connecting belt conveyors will be designed for stacking the cargoes; Or it can be connecting by a mobile telescopic conveyor to transfer the cargoes to the stockpiling yard or truck directly.

For a train loading conveyor system, the mobile telescopic conveyor can be used , which may receive the cargoes from a dump truck and transfer to train carriage; And a fixed hopper loading solution is also a ideal solution. The cargoes are conveyed to the hopper, and by using gravity valves and metering equipment etc machine, the train carriage receives the cargoes from the hopper directly.