belt conveyor cleaner Used in the mining, mineral processing and materials handling industries

- Model

- DT2EGH/DT3EGH/DT4EGH/DT2EGO/DT3EGO/DT4EGO

Review

Description

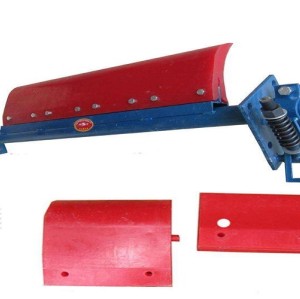

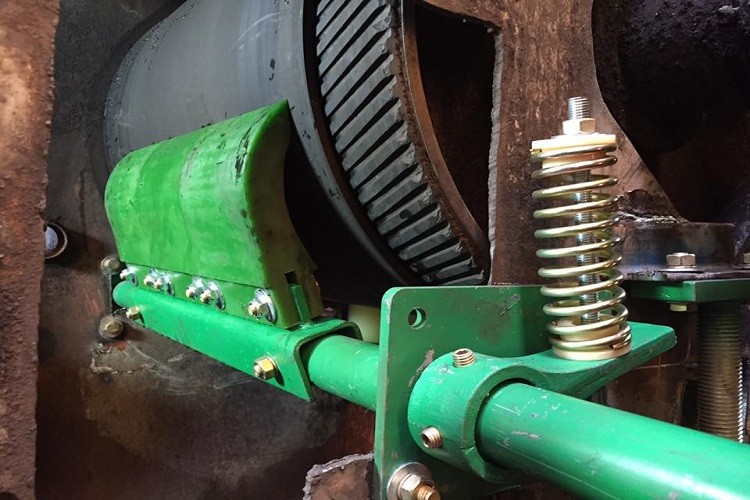

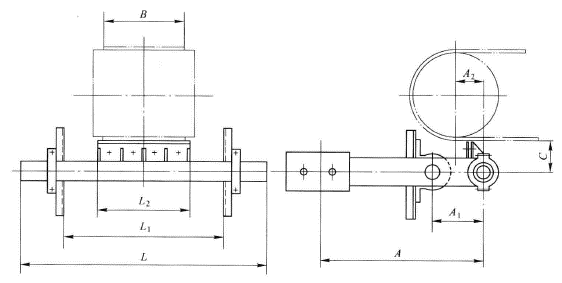

Head cleaner

It is installed at the discharge pulley on the head of the conveyor to clean the materials adhered to the working surface of the conveyor belt and make it fall into the head hopper.It is divided into two types according to different structural forms: heavy duty scraper cleaner, rubber spring alloy scraper cleaner.

(1) Heavy-duty scraper cleaner.

The scraper makes the scraper fixed on the arm frame closed to the load surface of the conveyor belt by virtue of the weight..It can be made of double scraper type to improve cleaning effect.

(2) Rubber spring alloy scraper cleaner

The squeegee presses the spring to make the squeegee fixed on the arm frame closed to the load surface of the conveyor belt, . The scraper materials is using high-performance polyurethane blades, suitable for meeting any complex working conditions;

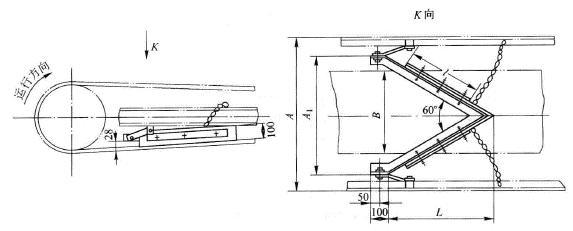

Vacuum section cleaner(non-loading cleaner)

The vacuum section cleaner is used to remove the debris falling on the non-working surface of the lower branch of the conveyor to protect the redirecting roller and the conveyor. It is generally installed in front of the roller to redirect to the roller and the first 90 ° of the vertical tensioning device to redirect to the roller. During the installation, the plow tip of the cleaner scraper should face the running direction of the conveyor belt in order to scrape the debris to the ground on both sides of the conveyor.

Features:

1. Extremely high cleaning performance. Adopting high-performance polyurethane material, it has a good cleaning effect and it can protect the conveyor belt;

2. Long service life. The cleaner body is made of alloy material, which is durable;

3. Save costs. The cleaning effect is good, no manual cleaning is needed; the cleaning process of the cleaner is automatically adjusted, and the scraper is easy to disassemble, which greatly saves labor costs

Specifications:

| Head belt cleaner specification ( mm ) | |||||||

| B | L | L1 | L2 | A | A1 | A2 | C |

| 400 | 890 | 600 | 420 | 530 | 200 | ≥60 | 120 |

| 500 | 990 | 700 | 520 | ||||

| 650 | 1140 | 850 | 680 | ||||

| 800 | 1360 | 1050 | 840 | 580 | |||

| 1000 | 1560 | 1250 | 1040 | ||||

| 1200 | 1810 | 1500 | 1240 | 630 | |||

| 1400 | 2010 | 1700 | 1440 | ||||

| 1600 | 2210 | 1900 | 1640 | 680 | |||

| 1800 | 2410 | 2100 | 1840 | ||||

| 2000 | 2610 | 2300 | 2040 | 730 | |||

| 2200 | 2910 | 2600 | 2240 | ||||

| 2400 | 3210 | 2900 | 2440 | 780 | |||

| Note :The thickness of Scraper is 10mm; However it is can be customized design based on the user's demand; | |||||||

| Vocuum section belt cleaner (mm) | |||

| B | A | A1 | L |

| 400 | 660 | 520 | 410 |

| 500 | 800 | 620 | 497 |

| 650 | 950 | 770 | 627 |

| 800 | 1150 | 970 | 800 |

| 1000 | 1350 | 1170 | 973 |

| 1200 | 1600 | 1420 | 1190 |

| 1400 | 1810 | 1630 | 1372 |

| 1600 | 2060 | 1880 | 1588 |

| 1800 | 2260 | 2080 | 1761 |

| 2000 | 2490 | 2290 | 1943 |

| 2200 | 2800 | 2610 | 2270 |

| 2400 | 3110 | 2940 | 2556 |

| Note :The thickness of Scraper is 10mm; However it is can be customized design based on the user's demand; | |||