Pipe Belt conveyor used in Electrical power plant

- Model

- DG100/GB150/DG150/DG200/DG250/DG/300/GD350/DG/400

Item specifics

- Color

- Customized

Review

Description

Description

The pipe belt conveyor is a kind of special belt conveyor developed on the basis of the trough belt conveyor. Its working principle is the same as that of the ordinary belt conveyor, which is driven by friction to move the conveyor belt and its materials. Most of the components can be used in common with the ordinary belt conveyor. The difference is that the conveyor belt needs to be rolled into a round tube, so it needs to use a polygon idlers (usually a hexagon idlers) to force the conveyor belt to form a round tube, and continuously transport various loose materials such as powder, granular and block materials in a closed manner. On the basis of continuous research and practice, a set of systematic standards and methods for design, manufacture, installation, commissioning and inspection have been gradually summed up for the circular tube belt conveyor, and a series of them have been formed.

The Pipe Conveyor also meets special requirements such as simultaneous material transport in the upper and lower strand and downhill transport with power-regeneration. It serves the cement and power plants, port handling concepts as well as chemical, steel and mining industries.

Application

It can be widely used in metallurgy, mines, coal, ports, power stations, building materials, chemical industry, light industry, machinery, petroleum and other industries.

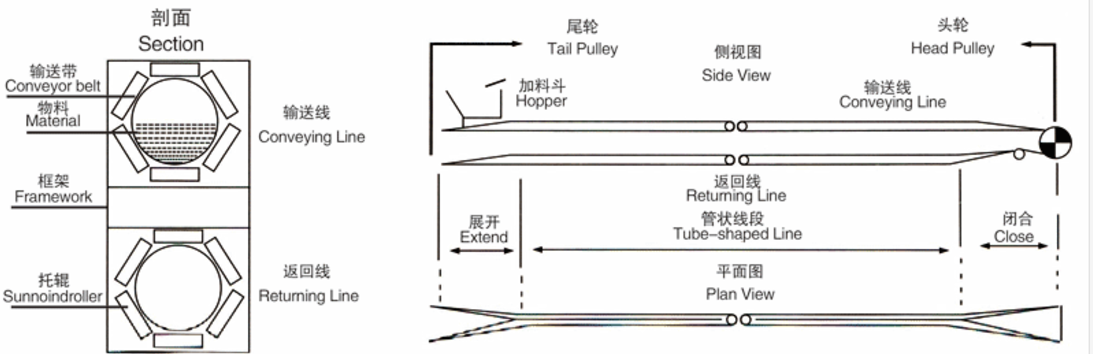

Pipe Belt Conveyor Structure Drawing

The main structure of the pipe belt conveyor can be divided into six parts: feeding section, rounding device, arc bending section, vertical section, unloading section and return section.

Features

1. Closed conveying materials: no scattering, flying or leakage during the conveying process. Since the return branch conveyor belt is also a closed circular tube, there is no need to worry about the scattering of materials adhering to the conveyor belt. Meanwhile, the foreigned materials will not fix in. Therefore, the pollution-free transportation is realized, the environment is purified, the belt gallery or cover of ordinary belt conveyor is not nessesory, and it can reduce the cost of infrastructure construction.

2. The conveyor line can be arranged in a curved space: because on the conveyor line, the conveyor belt is in a circular pipe structure, so that the conveyor can realize turning in the vertical and horizontal plane, bypass various obstacles and facilities, cross roads, railways, rivers, etc., without intermediate transfer. Therefore, a very economic general layout scheme is designed to achieve spatial bending layout with a small radius of curvature, and 90 ° bending can be achieved.

3. It can improve the conveying angle: the material is wrapped in the conveyor belt to increase the friction between the material and the inner surface of the conveyor belt, so it can improve the inclination of the belt conveyor.

4. No deviation: due to its structural principle, the phenomenon of belt deviation will not occur, which can reduce the maintenance cost. However, it is allowed that the conveyor belt of the circular tube belt conveyor has certain torsion.

5. Bidirectional conveying materials: under special process requirements, the lower circular tube belt conveyor can convey materials.

Technical Specifications

Pipe Diameter(mm) | Belt Width (mm) | Speed V (m/s) |

|||||||||

0.8 | 1.0 | 1.25 | 1.6 | 2.0 | 2.5 | 3.15 | 4.0 | 4.5 | 5.0 | ||

100 | 430 | 17 | 21 | 26 | 33 | -- | -- | -- | -- | -- |

-- |

150 | 600 | 38 | 47 | 59 | 76 | 95 | 118 | -- | -- | -- | -- |

200 | 750 | 66 | 83 | 103 | 133 | 166 | 207 | -- | -- | -- | -- |

250 | 1000 | 117 | 147 | 184 | 235 | 294 | 368 | 464 | -- | -- | -- |

300 | 1100 | 141 | 176 | 211 | 282 | 352 | 441 | 555 | 705 | -- | -- |

350 | 1300 | -- | 237 | 297 | 380 | 497 | 594 | 748 | 950 | 1069 | 1188 |

400 | 1600 | -- | 388 | 486 | 622 | 777 | 972 | 1224 | 1555 | 1749 | 1944 |

500 | 1900 | -- | 558 | 697 | 893 | 1116 | 1395 | 1758 | 2232 | 2511 | 2790 |

600 | 2250 | -- | 777 | 972 | 1244 | 1555 | 1944 | 2449 | 3110 | 3499 | 3888 |

700 | 2550 | -- | 1008 | 1260 | 1612 | 2016 | 2520 | 3175 | 4032 | 4536 |

5040 |

800 | 3100 | -- | 1454 | 1818 | 2327 | 2908 | 3636 | 4580 | 5817 | 6544 | 7272 |

Note:

Volume conveying capacity is shown in the table, which is calculated by horizontal transportation and cross-sectional area of 75%.