Characteristics and structure of belt conveyor

- Share

- Issue Time

- Jun 22,2021

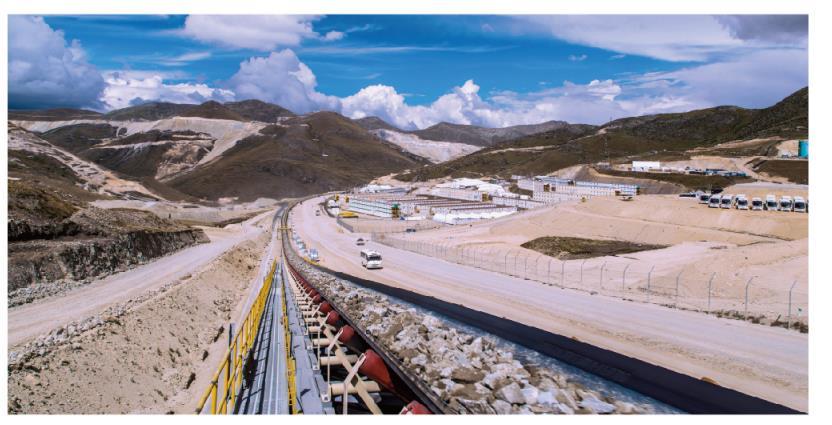

Because the belt conveyor has the advantages of long conveying distance, large traffic volume, continuous conveying, large conveying capacity, simple structure, convenient maintenance, low cost and strong versatility, it has been widely used in mine production.

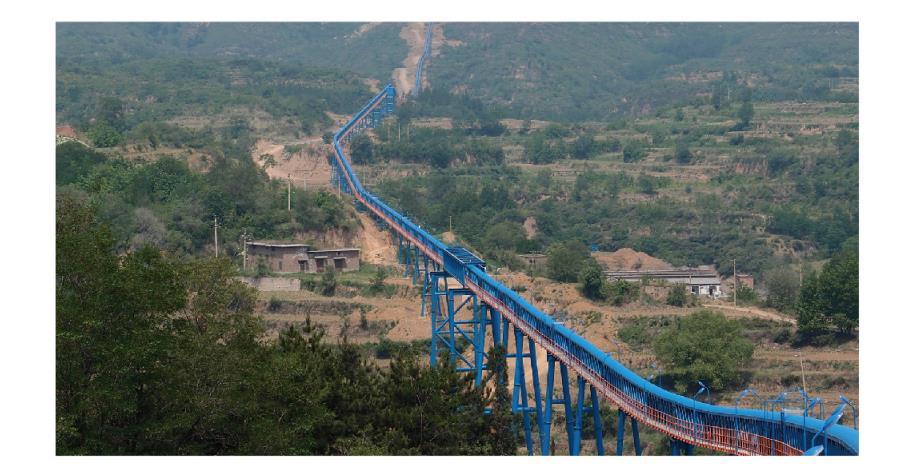

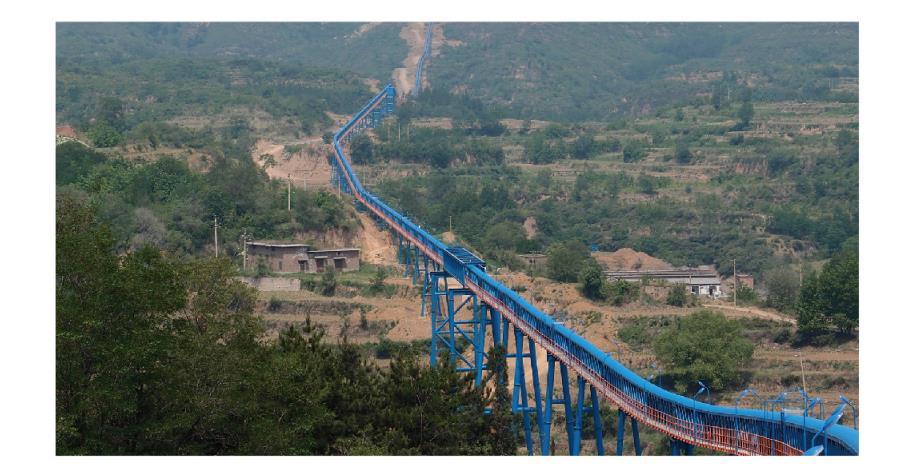

Structures of belt conveyor

The universal belt conveyor is composed of conveyor belt, idler, roller and drive, brake, tension, change direction, loading, unloading, cleaning and other devices. Belt width is the main technical parameter of belt conveyor. Idler is divided into single roller, double roller and multi roller, including trough roller, flat roller, centering roller and buffer roller. The trough roller supports the load branch, which is used to transport the granular materials; The self-aligning idler is used to adjust the transverse position of the belt to avoid deviation; The buffer idler is installed at the material receiving position to reduce the impact of the material on the belt. The drum is divided into driving drum and steering drum. The driving drum is the main part of power transmission, which is divided into single drum, double drum and multi drum. The function of the tensioning device is to make the conveyor belt reach the necessary tension, so as to avoid slipping on the driving drum, and ensure the deflection of the conveyor belt between the idlers within the specified range.