What are the characteristics of belt conveyor tensioning devices?

- Share

- Issue Time

- Apr 1,2020

In order to drive a conveyor belt with a full load, the belt must be under optimum tension to prevent it from slipping on the drive pulley.

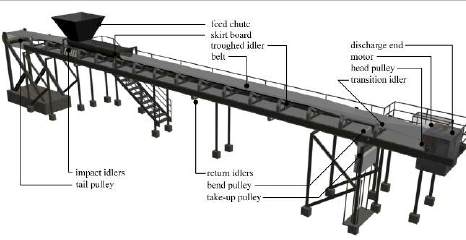

The function of the tensioning device is to generate a certain pre-tension in the conveyor belt to prevent it from slipping on the driving pulley; at the same time, control the deflection of the conveyor belt between the idlers to reduce resistance and avoid spreading. The structure of the tensioning device mainly includes screw type, heavy weight type (also divided into trolley type and vertical type), winch type (also divided into fixed winch type and automatic winch type) screw type tensioning device. On the carriage of the nut, the carriage can be moved on the tail-stock. Turn the screw on the tail-stock to move the drum back and forth to adjust the tension of the conveyor belt. It has a simple structure, but it is not easy to control the tension force. The tension force cannot be constant during operation and the tension stroke is small. Therefore, it is only used for conveyors with a length less than 80m and a small power.

The screw take-up has the advantage of simplicity and is located at the base of the conveyor. The two bearings of the tail pulley shaft are mounted on rails. Each bearing can be adjusted individually forward or backwards by means of long bolts usually termed "take-up screw".

The heavy-weight tension device uses the weight of the iron plates to tension the conveyor belt.The tension pulley is awarded on a trolley that can move on the frame. It has a simple structure, can maintain a constant tension, and is fast and reliable. It is suitable for conveyors with long machine lengths and large power. The characteristic of the vertical weight type is that the space under the conveying corridor can be used. The disadvantage is that there are more redirecting rollers, and it is difficult to increase and decrease the weight and maintain the rollers. The fixed winch type tensioning device uses a set of multi-speed pulleys and an electric hoist to tension the conveyor belt once when the conveyor is stopped (or running), and it is no longer or rarely adjusted. Its characteristics are similar to the screw-type tensioning device, but it can reflect the tension force and the tensioning stroke is large.

The structure of the automatic winch is the same as that of the fixed winch, but it has an additional set of electrical control systems that can detect the tension value and allow the winch to automatically rotate forward and reverse according to the tension when the conveyor is running. The purpose is to make the conveyor have Large in-band tension to avoid slipping. During normal operation, it is similar to a hammer-type tensioning device, which keeps the tension of the belt constant at a small value. The automatic winch control system is complicated and prone to failure, so a hammer-type tensioning device should be selected as much as possible.

SKE machinery is focusing on bulk material belt conveyor handling products and solution, our technical engineer will recommnend the right tension take up device for belt conveyors according to the specifications.